In modern industrial environments, gear shaper cutters play a crucial role in achieving precision, productivity, and long-term performance. These cutters are constantly exposed to high levels of productivity demands, especially in industries where accuracy and efficiency are non-negotiable. When selecting gear manufacturing equipment, many factors must be considered to ensure the final components meet the required standards. No matter how advanced the machines become, the tools and cutters used in the process face continuous wear and must be durable enough to maintain accuracy over time. This is why choosing reliable gear shaper cutter suppliers in India has become so important—they provide high-quality parts, dependable service, and strong warranties.

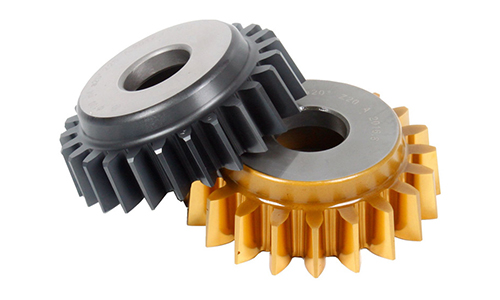

Gear shaper cutters are designed to deliver consistent results in the gear manufacturing process. They support smooth operation, enhance production efficiency, and help industries maintain high-quality standards. Understanding their benefits can help manufacturers choose the right tools for their applications.

1. Quality You Can Depend On

One of the biggest advantages of using high-quality gear shaper cutters is the guaranteed performance they deliver. During production, precise tools are essential for shaping sprocket wheels, gears, and other components that must meet exact standards. These cutters contribute directly to the strength and durability of the helical gears being produced.

To manufacture accurate equipment, the expansion and performance capacities of the tools must be consistently monitored. The gear shaping process involves multiple elements working together at different levels, especially when dealing with non-parallel shafts or spiral tooth forms. Because of this, gear shaper cutters must be adaptable, long-lasting, and capable of maintaining their shape under heavy loads.

High-quality cutters from trusted suppliers offer that reliability. They help manufacturers reduce errors, produce gears with consistent tooth profiles, and achieve long-term stability in their operations.

2. Precision and Accuracy in Every Application

In any gear manufacturing process, precision is the key factor that determines the quality of the final product. When working with complex components such as non-parallel gears, high accuracy becomes even more important. Gear shaper cutters ensure smooth transmission of motion between parts, even under challenging conditions.

Manufacturers have a wide variety of mobility and design options to choose from depending on the specific requirements of their projects. Some operations may require lightweight tools or space-saving designs, while others might need cutters capable of handling heavy loads or high temperatures.

Gear shaper cutters offer superior performance across these scenarios. Their design ensures the accuracy of gear teeth and maintains the correct form throughout the shaping process. For example, during high-temperature operations, the cutters must remain stable and avoid deformation. The ability to maintain both form and function is what makes gear shaper cutters indispensable in modern production lines.

When properly used, they guarantee high precision, smooth connectivity between parts, and reliable operation over long periods. This makes them essential tools for industries seeking both quality and consistency.

3. Long-Term Effectiveness and Durability

Durability is another major benefit of investing in quality gear shaper cutters. These tools must handle continuous workloads, adapt to modern applications, and remain dependable for years. Well-designed cutters offer strong structural integrity, resistance to wear, and the ability to perform in demanding environments.

Manufacturers often require solutions that can support different gear designs, including spiral and helical gears. Gear shaper cutters meet this need by providing flexibility and consistency across various gear sizes and shapes. Their robust construction ensures that even when used for complex operations, they deliver the same level of accuracy throughout their lifespan.

Long-term effectiveness also involves reduced downtime. When cutters perform reliably, manufacturers spend less time on repairs, adjustments, or replacements. This improves productivity and ensures smoother workflow throughout the production line.

4. Reducing the Cost of Ownership

While high-quality gear shaper cutters may involve a higher initial cost, they significantly reduce long-term ownership expenses. Better cutters mean fewer replacements, less maintenance, and minimal production interruptions. This directly lowers operational costs and increases overall efficiency.

Manufacturers in India, in particular, benefit from choosing durable cutters because they support longer production runs without compromising on quality. Improved surface finishes, better tooth accuracy, and smoother gear with helical shaper cutter operation all contribute to reducing energy consumption and minimizing waste.

When companies invest in long-lasting and reliable tools, they improve both productivity and product quality. These advantages ultimately result in a lower cost of ownership and a more efficient manufacturing process.

Conclusion

Gear shaper cutters are essential tools in modern industrial applications. Their ability to deliver precision, durability, and consistency makes them invaluable for producing high-quality gears. Whether used for helical gears, sprocket wheels, or customized industrial components, these cutters ensure accurate shaping and long-term performance.

Indian suppliers of gear shaper cutters offer reliable products backed by strong warranties and excellent service. By choosing high-quality cutters, manufacturers can enhance productivity, reduce long-term costs, and maintain the highest standards of gear manufacturing.

In a world where precision is everything, investing in the right gear shaper cutters is a smart decision that leads to better efficiency, improved product quality, and long-lasting performance.