Maintaining precise pH levels is a critical aspect of chemical processing in industries ranging from pharmaceuticals and food production to petrochemicals and wastewater treatment. Accurate pH measurement ensures product quality, process efficiency, and compliance with safety and environmental regulations. In these applications, a reliable pH sensor for water is an essential tool for monitoring and controlling chemical reactions, water treatment processes, and industrial effluents.

In chemical processing, water often serves as a solvent, coolant, or reagent carrier. Any deviation in pH can impact chemical stability, reaction rates, and product consistency. Traditional manual testing methods are insufficient for complex industrial operations where real-time monitoring and rapid adjustments are required. Digital and industrial-grade pH sensors provide continuous, precise measurements, enabling operators to maintain optimal conditions throughout the production process.

A pH Sensor for Water plays a pivotal role in industrial chemical processes by providing accurate readings for immediate decision-making. By integrating these sensors into process control systems, industries can automatically adjust chemical dosages, prevent corrosion or scaling, and reduce downtime caused by improper water chemistry. This leads to improved efficiency, reduced operational costs, and consistent product quality.

Monitoring Water Chemistry in Chemical Reactors

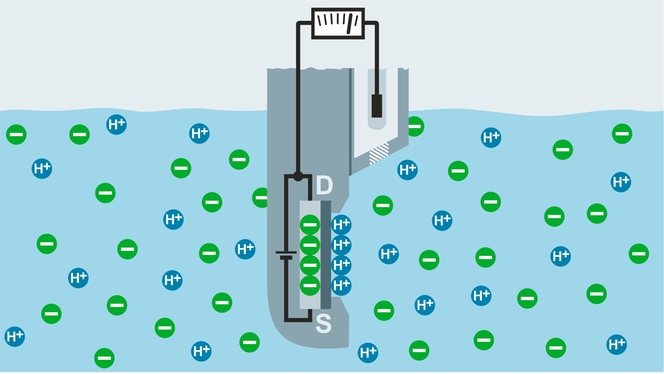

Chemical reactors often require tightly controlled water chemistry to ensure reactions proceed as intended. A pH sensor measures hydrogen ion concentration in real time, allowing operators to maintain the desired acidity or alkalinity for optimal reaction efficiency. Continuous pH monitoring prevents deviations that could result in incomplete reactions, formation of unwanted byproducts, or compromised product purity.

In processes where multiple reagents are combined, pH measurement is critical for balancing reactions. For example, in pharmaceutical manufacturing, maintaining the correct pH is essential for drug stability and efficacy. Similarly, in the production of specialty chemicals, precise pH control ensures consistent molecular structure and functionality of the final product.

Ensuring Safety and Compliance

Industrial chemical processes often involve hazardous or reactive substances. Monitoring pH levels helps ensure worker safety and compliance with environmental regulations. Improper pH control can lead to corrosive conditions, creating equipment damage and safety risks. Wastewater discharges also require strict pH compliance to prevent environmental harm, making pH sensors essential tools for meeting regulatory standards.

Automated pH monitoring reduces human error and provides documented evidence of compliance. Data from sensors can be logged, analyzed, and shared with regulatory authorities, supporting audits and environmental reporting. This capability is particularly valuable in industries with stringent safety and environmental oversight.

Process Optimization and Cost Efficiency

By providing accurate, real-time data, pH sensors support process optimization. Automated systems can adjust chemical dosing dynamically, minimizing waste and reducing chemical costs. Maintaining proper pH levels prevents scaling, corrosion, or fouling of equipment, extending the lifespan of reactors, pipelines, and pumps. This not only reduces maintenance costs but also enhances overall operational efficiency.

Industries with large-scale water usage, such as cooling water systems or boiler operations, benefit significantly from continuous pH monitoring. Sensors detect small changes that could otherwise escalate into costly problems, ensuring reliable and efficient operation over long periods.

Applications Across Industrial Sectors

The versatility of pH sensors makes them indispensable across various industrial applications:

- Pharmaceuticals: Ensures precise reaction conditions and product stability.

- Food and Beverage: Maintains water quality for processing, cleaning, and ingredient mixing.

- Petrochemical: Monitors water chemistry in refining and chemical synthesis.

- Wastewater Treatment: Controls effluent pH to meet environmental discharge regulations.

- Electroplating and Metal Finishing: Protects equipment and ensures consistent coating quality.

In all these sectors, accurate pH measurement contributes to product quality, safety, and operational efficiency.

Maintenance and Calibration

To maintain reliability, industrial pH sensors require regular calibration with standard buffer solutions and routine cleaning to remove deposits or chemical residues. High-quality sensors are designed for harsh environments, including high temperature, pressure, and chemical exposure, but periodic maintenance ensures consistent performance and prolongs sensor life.

Conclusion

A pH sensor for water is a vital instrument in chemical processing industries, providing accurate, real-time measurements essential for process control, safety, and regulatory compliance. From optimizing chemical reactions and reducing operational costs to protecting equipment and the environment, these sensors support efficient and sustainable industrial operations. Proper integration, calibration, and maintenance of pH sensors ensure that industries achieve consistent water quality and reliable production outcomes.