The field of pipeline inspection is evolving rapidly, driven by the need for more precise, efficient, and data-driven solutions. Traditional sewer camera systems have provided visual access to underground pipelines for decades, but the integration of smart technologies is transforming the industry. Sewer camera manufacturers are now incorporating digital intelligence, automation, and data analytics to enhance inspection capabilities, streamline operations, and improve decision-making for municipalities, contractors, and industrial operators.

Integration of Digital and Smart Features

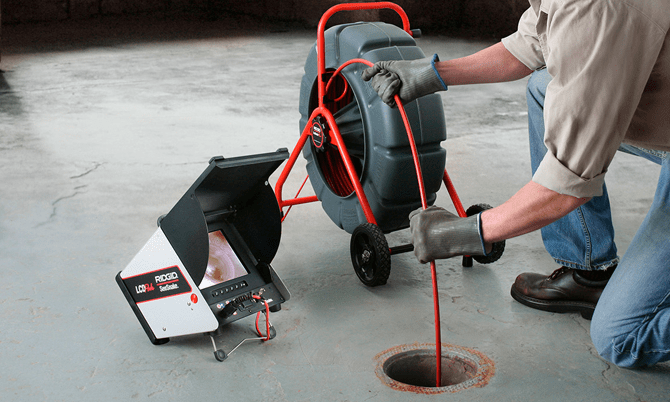

Smart inspection technologies involve integrating sensors, software, and connectivity features into traditional sewer camera systems. Manufacturers like Sewer Camera Manufacturers are adopting these solutions to offer operators enhanced functionality. Modern cameras can now record high-definition video, capture real-time data, and interface with software platforms for immediate analysis. This integration allows inspectors to detect defects, measure distances, and document issues with greater precision than ever before, while reducing the need for repeated inspections.

Remote Monitoring and Connectivity

One of the key advances in smart inspection is remote monitoring. Smart sewer cameras can transmit live video and sensor data to operators at a distance, allowing inspections to be conducted more safely and efficiently. Manufacturers are equipping systems with wireless connectivity, enabling teams to access pipeline conditions in real time without physically being present at every inspection site. This capability not only increases safety but also enables faster response times to emerging infrastructure problems.

Advanced Imaging and Sensor Technologies

Sewer camera manufacturers are improving image clarity and analysis through smart technologies. High-resolution cameras are now paired with sensors that measure pipe diameter, flow rate, and structural integrity. Some systems incorporate 360-degree imaging or pan-and-tilt camera heads for comprehensive views of the pipeline interior. These technological enhancements enable inspectors to identify cracks, corrosion, blockages, and other defects with unparalleled accuracy, which was previously difficult using standard camera systems.

Data Management and Analysis

Smart inspection technologies rely heavily on data collection and management. Manufacturers provide software that stores, organizes, and analyzes inspection data, allowing for long-term monitoring and predictive maintenance. Digital records of pipeline conditions can be compared over time, helping municipalities and operators anticipate failures before they occur. By integrating these capabilities into sewer camera systems, manufacturers enhance operational efficiency and support data-driven decision-making in pipeline management.

Automation and AI Integration

Another area of focus for manufacturers is automation and artificial intelligence. Some modern sewer cameras are equipped with AI-driven algorithms that can detect defects automatically and flag potential issues for further inspection. This reduces human error and accelerates the inspection process. Manufacturers are increasingly investing in smart technologies that not only capture data but also interpret it, making inspections more proactive and less labor-intensive.

Usability Enhancements for Operators

Smart technologies also improve usability for field operators. Integrated touchscreens, intuitive control software, and automated functions reduce the learning curve and streamline inspection workflows. Sewer camera manufacturers are designing interfaces that allow operators to focus on analysis rather than complex system controls, making it easier to conduct accurate inspections in challenging environments.

Scalability and Modular Systems

To meet the diverse needs of municipal, industrial, and commercial users, manufacturers are designing modular systems that can be upgraded with smart features. Operators can add additional sensors, recording modules, or AI-driven analysis tools as needed. This adaptability allows organizations to scale their inspection capabilities without replacing entire systems, reducing cost and maximizing long-term utility.

Ensuring Reliability in Smart Systems

Despite the integration of advanced technologies, manufacturers maintain a strong focus on durability, waterproofing, and mechanical reliability. Smart features must function consistently in harsh underground environments, and manufacturers conduct rigorous testing to ensure cameras remain operational under pressure, moisture, and debris exposure. Balancing intelligence with reliability is critical for ensuring that smart inspection systems deliver accurate and dependable results.

Conclusion: The Future of Smart Sewer Inspections

Sewer camera manufacturers are embracing smart inspection technologies to transform the way pipelines are monitored and maintained. Through integration of digital systems, remote monitoring, AI, and advanced imaging, these manufacturers enhance inspection accuracy, operator efficiency, and infrastructure management. By adapting to emerging technologies, they ensure that sewer inspection remains a reliable, data-driven, and forward-looking practice capable of meeting the growing demands of modern infrastructure.