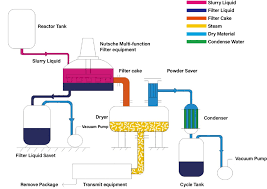

Filtration is a critical step in many industrial processes, including chemical manufacturing, pharmaceuticals, and food production. Achieving high filtration efficiency ensures consistent product quality, minimizes waste, and optimizes production timelines. Traditional filtration methods, such as simple filter presses or plate filters, often struggle with challenges like uneven cake formation, slow liquid removal, and contamination risks. Agitated Nutsche Filters have emerged as a highly effective solution to these challenges, offering integrated filtration, washing, and drying in a single vessel while enhancing process control and efficiency.

One of the primary reasons an Agitated Nutsche Filter improves filtration efficiency is its combination of agitation and controlled pressure or vacuum operation. The agitator continuously stirs the solid cake during filtration, preventing compaction and channeling, which are common issues in conventional filtration systems. This mechanical action ensures that liquid flows uniformly through the filter cake, accelerating the separation process and improving overall throughput. Additionally, the enclosed system minimizes exposure to contaminants, maintaining product purity and ensuring consistent filtration results.

Uniform Cake Formation

Uneven cake formation is a major factor that reduces filtration efficiency in conventional systems. In an agitated Nutsche filter, the agitator evenly distributes solids across the filter plate, promoting a uniform cake thickness. This uniformity allows for consistent liquid flow and reduces the risk of localized high-resistance zones that slow filtration. By maintaining a consistent cake structure, operators can achieve predictable filtration rates and avoid frequent interruptions caused by uneven or compacted cakes.

Enhanced Washing Capabilities

Washing the filter cake is often necessary to remove impurities, residual reactants, or solvents from the solid product. Agitated Nutsche filters significantly improve the washing process by ensuring that the wash liquid penetrates the entire cake evenly. The agitator gently moves the solids during washing, breaking up any layers that could impede solvent penetration. This results in more efficient removal of unwanted substances, lower solvent usage, and a higher-purity final product. Faster and more uniform washing directly contributes to improved overall filtration efficiency.

Integrated Drying Function

Moisture content in the filter cake can affect the quality and stability of the final product. Agitated Nutsche filters are designed with jacketed vessels that allow heating through steam, thermal oil, or other heat transfer fluids. The agitator ensures even heat distribution throughout the solid cake, accelerating moisture removal and preventing hotspots that could degrade sensitive materials. By combining filtration, washing, and drying within a single vessel, these systems reduce the need for transferring materials between separate units, minimizing product loss, contamination risks, and overall processing time.

Pressure and Vacuum Control

Agitated Nutsche filters operate efficiently under controlled pressure or vacuum conditions, which further enhances filtration rates. Vacuum-assisted filtration draws liquid through the cake more quickly than gravity alone, reducing cycle times. Pressure filtration can be used for high-viscosity slurries, ensuring rapid separation even with dense solids. When combined with agitation, these features allow operators to optimize conditions for different materials, improving both speed and consistency of filtration.

Reduced Risk of Contamination

Maintaining product purity is essential, particularly in pharmaceutical and specialty chemical production. The closed design of agitated Nutsche filters protects the solid and liquid phases from airborne contaminants and operator exposure. This containment also allows for safe handling of hazardous, toxic, or pyrophoric materials. By reducing contamination risks, these filters improve overall process efficiency by minimizing the need for reprocessing or batch rejection.

Automation and Process Control

Modern agitated Nutsche filters are often equipped with advanced automation and monitoring systems. Sensors track parameters such as cake thickness, vacuum levels, pressure, and temperature in real-time. Automated controls adjust agitation speed, vacuum, or heating to maintain optimal conditions throughout the filtration cycle. This precise control ensures reproducibility, reduces operator error, and maximizes efficiency across multiple batches. The ability to collect and analyze data also supports process optimization and regulatory compliance.

Versatility and Adaptability

Agitated Nutsche filters are capable of handling a wide range of materials, including fine powders, viscous slurries, and abrasive solids. Their adaptability allows manufacturers to process different product types without major equipment modifications. The flexibility in agitation speed, vessel size, and filter media ensures that operators can optimize filtration conditions for each specific application, further improving efficiency and overall throughput.

In conclusion, agitated Nutsche filters improve filtration efficiency through a combination of uniform cake formation, enhanced washing, integrated drying, and controlled pressure or vacuum operation. Their enclosed design reduces contamination risks, while automation and advanced process control ensure consistent, high-quality results. By integrating multiple processing steps in a single system, agitated Nutsche filters not only enhance efficiency but also reduce labor, energy consumption, and operational costs, making them an indispensable tool in modern industrial filtration applications.