Bringing an idea to life is never easy. Whether it’s a new consumer gadget, industrial machine, or medical device, the journey from concept to market-ready product involves multiple stages of design, testing, and refinement. This is where a prototype development company becomes a crucial partner.

A prototype development company specializes in transforming conceptual ideas into working prototypes, allowing inventors, startups, and businesses to test, validate, and refine their products before mass production. By leveraging advanced technologies and expert engineering, these companies reduce risk, accelerate development, and improve the chances of commercial success.

This comprehensive guide explores the role of a prototype development company, the process of prototype creation, and how businesses can benefit from professional prototyping services.

What Is a Prototype Development Company?

A prototype development company is a specialized firm that provides end-to-end services for creating functional or conceptual prototypes of new products. These prototypes serve as tangible representations of ideas, enabling companies to:

- Test feasibility and functionality

- Identify design flaws

- Validate user experience

- Secure funding or investment

- Prepare for manufacturing

By combining expertise in industrial design, mechanical engineering, electronics, software, and 3D modeling, a prototype development company bridges the gap between imagination and reality.

Why Businesses Need a Prototype Development Company

1. Reduce Development Risks

Launching a product without prototyping is risky. Prototypes help identify design flaws, technical challenges, and usability issues early, reducing the chances of costly failures during production.

2. Accelerate Time to Market

Experienced prototype development companies streamline the product development cycle, allowing businesses to test, iterate, and refine ideas faster. This speed is essential in competitive markets.

3. Optimize Costs

Prototyping early prevents expensive redesigns and material waste. By validating designs before mass production, businesses save both time and money.

4. Improve Product Quality

Professional prototyping ensures products are functional, reliable, and user-friendly. This improves overall quality and enhances customer satisfaction.

5. Facilitate Investment and Funding

A working prototype can be presented to investors, partners, or crowdfunding platforms, helping secure funding and support for full-scale production.

The Prototype Development Process

A professional prototype development company follows a structured process to ensure efficient and effective outcomes:

1. Conceptualization & Idea Evaluation

The first step involves understanding the client’s idea and defining the objectives. Activities include:

- Market research

- Feasibility studies

- Technical assessment

- Requirement gathering

At this stage, the company collaborates closely with the client to ensure the concept aligns with business goals.

2. Industrial Design & 3D Modeling

Industrial designers create detailed sketches and 3D models to visualize the product. Key aspects include:

- Aesthetics and ergonomics

- Material selection

- Form, fit, and functionality

- User interface and interaction design

Advanced CAD tools allow designers to create realistic, precise models for evaluation and refinement.

3. Prototype Engineering

Engineering teams transform the concept into a working model. This may involve:

- Mechanical engineering for structural components

- Electronics and embedded systems design for smart devices

- Firmware and software integration for digital products

- Power management and optimization

The goal is to create a functional prototype that closely resembles the final product in performance.

4. Rapid Prototyping Techniques

Prototype development companies use various technologies to build prototypes quickly and efficiently:

- 3D Printing: Ideal for creating intricate and precise components.

- CNC Machining: For durable and accurate parts.

- Laser Cutting: For precise material shaping.

- Injection Molding: For creating realistic functional prototypes in plastics.

Selecting the right prototyping method depends on the product type, budget, and timeline.

5. Testing and Validation

Prototypes are tested rigorously to ensure they meet functional, safety, and user requirements. Testing may include:

- Performance and functionality tests

- Usability and user experience evaluation

- Environmental and durability testing

- Safety and compliance checks

Feedback from testing guides design improvements and ensures the product is market-ready.

6. Iteration and Refinement

Based on testing results, the prototype undergoes iterative improvements. This phase ensures:

- Design flaws are corrected

- User experience is enhanced

- Manufacturing feasibility is verified

Iteration is a key advantage of working with a professional prototype development company.

7. Preparing for Mass Production

After successful prototyping, the product is ready for manufacturing. Prototype development companies assist with:

- Bill of Materials (BOM) creation

- Supplier and vendor selection

- Manufacturing documentation and tooling

- Quality control planning

This ensures a smooth transition from prototype to large-scale production.

Benefits of Hiring a Prototype Development Company

- Expertise Across Multiple Disciplines: Industrial design, mechanical engineering, electronics, and software.

- Faster Development: Streamlined processes and advanced tools accelerate timelines.

- Risk Mitigation: Early testing identifies and resolves potential issues.

- Cost Efficiency: Reduced material waste and fewer redesigns.

- Investor Readiness: Tangible prototypes enhance credibility and funding opportunities.

- Custom Solutions: Tailored prototyping methods based on product requirements.

Working with a prototype development company empowers businesses to innovate confidently.

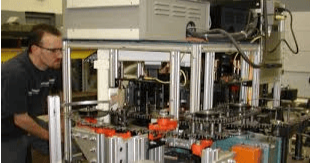

Industries That Benefit from Prototyping Services

- Consumer electronics

- Healthcare and medical devices

- Automotive and transportation

- Industrial machinery

- Wearables and smart devices

- Aerospace and defense

- Robotics and automation

Almost any industry launching new products can benefit from professional prototype development.

FAQ: Prototype Development Company

1. How long does prototyping take?

Depending on complexity, prototypes can take from a few weeks to several months.

2. How much does prototyping cost?

Costs vary widely, from $5,000 for simple devices to $100,000+ for complex electronics or industrial machinery.

3. Can a prototype be used for crowdfunding campaigns?

Yes, a working prototype can demonstrate feasibility and attract investors or crowdfunding support.

4. Do prototype development companies also handle product manufacturing?

Many companies provide manufacturing support, including supplier selection, tooling, and quality assurance.

5. Is intellectual property (IP) protected during prototyping?

Reputable companies implement NDAs and IP protection agreements to safeguard client ideas.

6. Can startups benefit from a prototype development company?

Absolutely. Startups often rely on prototyping services to reduce risk, validate ideas, and secure funding.

Disclaimer

This article is for informational purposes only and does not constitute engineering, legal, or manufacturing advice. Businesses should consult qualified professionals before developing or launching any product prototypes development company.