Logistics operations depend heavily on speed, accuracy, and efficiency when moving goods from one point to another. As global supply chains expand and e-commerce continues to grow, warehouses and distribution centers require equipment that can handle high shipment volumes while reducing manual labor. Telescopic belt conveyors have become an important part of modern logistics systems because they simplify loading and unloading processes and improve workflow productivity.

In busy shipping facilities, time-saving material-handling solutions can make a significant difference in operational performance. A telescopic conveyor system can extend directly into trucks or containers, allowing goods to be transferred quickly and safely between transport vehicles and storage areas. Many logistics companies rely on a telescopic belt conveyor to streamline dock operations, reduce worker fatigue, and maintain consistent package flow during peak shipping periods. By minimizing manual carrying and walking distances, these conveyors help distribution centers maintain efficiency even when handling large volumes of goods.

Truck Loading and Unloading Operations

One of the most common applications of telescopic belt conveyors in logistics is truck loading and unloading. In traditional operations, workers must carry packages into trailers manually or use forklifts for transport. This process can be slow, physically demanding, and prone to errors or product damage.

Telescopic belt conveyors solve this problem by extending directly into the truck. Workers can place packages onto the conveyor at the dock, and the belt transports them smoothly into the vehicle. During unloading, the conveyor works in reverse, bringing goods from the truck into the warehouse. This reduces loading times, improves safety, and allows companies to process shipments more efficiently.

E-Commerce Fulfillment Centers

E-commerce fulfillment centers handle thousands of packages every day, often under strict delivery deadlines. Telescopic belt conveyors play a critical role in these environments by supporting continuous package movement between sorting areas and shipping docks.

Because fulfillment centers frequently manage different package sizes and shipment volumes, flexible equipment is essential. Telescopic conveyors can adjust their length to match truck size and loading requirements, making them ideal for fast-paced distribution operations. Their ability to maintain steady product flow helps prevent bottlenecks and ensures that orders are shipped on time.

Courier and Parcel Distribution Facilities

Courier and parcel delivery companies rely on efficient sorting and transport systems to keep up with daily shipping demands. Telescopic belt conveyors are commonly installed at loading docks where delivery vehicles are constantly arriving and departing.

These conveyors allow workers to load parcels directly into delivery trucks without unnecessary lifting or carrying. This not only speeds up operations but also reduces the risk of injuries caused by repetitive movement. In high-volume parcel hubs, telescopic conveyors contribute to smoother workflow coordination and improved shipment accuracy.

Warehouse Dock Management

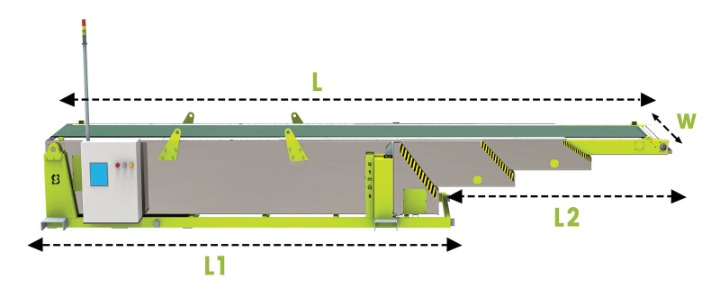

Warehouse dock management involves coordinating incoming and outgoing shipments while maintaining organized material flow. Telescopic belt conveyors help optimize dock space by providing a compact solution that can extend only when needed.

When not in use, the conveyor retracts to save space and keep loading areas clear. When a truck arrives, the system can quickly extend into position. This flexibility allows warehouses to handle multiple vehicles efficiently without requiring permanent conveyor lines for each dock door.

In addition, adjustable height features on some telescopic conveyors allow them to align with different truck floor levels, ensuring smooth product transfer regardless of vehicle type.

Manufacturing and Distribution Integration

Manufacturing facilities often integrate logistics operations with production output. Finished goods must be transported from assembly or packaging lines to shipping areas quickly and safely. Telescopic belt conveyors help bridge this gap by connecting warehouse storage zones with outbound transportation.

By automating part of the shipping process, manufacturers can reduce delays between production completion and product delivery. This improves supply chain coordination and ensures that products reach customers faster.

Airport Cargo Handling

Airport cargo terminals are another important area where telescopic belt conveyors are used. Air freight operations require fast loading and unloading of cargo containers and trucks to meet strict flight schedules.

Telescopic conveyors allow cargo handlers to move packages efficiently between storage areas and transport vehicles. Their extendable design makes them suitable for handling different container sizes, improving cargo transfer speed and reducing manual labor in time-sensitive environments.

Benefits for Logistics Efficiency

Across all logistics applications, telescopic belt conveyors provide several operational advantages. They reduce manual handling, improve worker safety, and increase loading speed. These improvements help companies lower labor costs while maintaining high productivity levels.

Another important benefit is product protection. Conveyor belts move goods smoothly and consistently, reducing the chances of items being dropped or damaged during loading. This is particularly valuable for fragile or high-value shipments.

Scalability is also a key advantage. As logistics operations grow, telescopic conveyor systems can be integrated into larger material-handling networks that include sorting systems, fixed conveyors, and warehouse automation technologies.

Conclusion

Telescopic belt conveyors have become an essential tool in modern logistics operations. From truck loading and parcel distribution to e-commerce fulfillment and airport cargo handling, these systems support faster and safer movement of goods across supply chains. Their extendable design, operational flexibility, and efficiency benefits make them a practical solution for companies seeking to improve dock operations and overall logistics performance. As distribution demands continue to increase, telescopic belt conveyors will remain a valuable investment for optimizing material-handling processes.