Water soluble packaging machines have become a crucial part of modern manufacturing, particularly in industries such as detergents, cleaning products, pharmaceuticals, and healthcare. These machines enable single-dose packaging using films that dissolve completely in water, providing convenience, safety, and environmental sustainability. As demand for eco-friendly and user-friendly packaging continues to rise, manufacturers are exploring innovations in water soluble packaging machine technology to improve efficiency, accuracy, and versatility.

Growing Demand for Automation

One of the most significant trends in water soluble packaging machine technology is increased automation. Traditional manual or semi-automated systems are being replaced by fully automated machines that integrate multiple functions, including film feeding, forming, filling, sealing, and cutting. Automation reduces human intervention, minimizes errors, and enhances production speed, allowing manufacturers to meet growing market demand efficiently.

Advanced automated systems also provide precise dosing and consistent sealing, which is especially important in industries where product accuracy and hygiene are critical. Automation ensures uniformity across large production volumes, reduces material waste, and improves overall operational efficiency. As technology evolves, these systems are becoming smarter, with enhanced monitoring, diagnostics, and self-correcting capabilities to optimize output.

Integration of Smart Technologies

The future of water soluble packaging machines will heavily rely on smart technologies and data-driven manufacturing. Integration of sensors, IoT (Internet of Things) devices, and real-time monitoring systems allows manufacturers to track production parameters, detect anomalies, and make immediate adjustments. Smart machines can optimize dosing, sealing, and cutting operations based on environmental conditions, film properties, and product type, reducing waste and improving quality.

A modern Water Soluble Packaging Machine equipped with smart technologies can provide predictive maintenance alerts, helping operators identify potential issues before they result in downtime. This approach increases operational efficiency, extends machine lifespan, and ensures uninterrupted production. Data analytics from smart machines also enables manufacturers to analyze trends, streamline processes, and make informed decisions for future production planning.

Energy Efficiency and Sustainability

Sustainability is a growing priority across all industries, and water soluble packaging machines are no exception. Future trends include the development of machines with enhanced energy efficiency, reducing electricity consumption and environmental impact. Variable frequency drives, precision heating systems, and optimized material handling are being integrated to reduce power usage while maintaining high-speed operation.

Additionally, advancements in biodegradable and environmentally friendly water soluble films are shaping machine design. Packaging machines are being adapted to handle thinner, more delicate films without compromising speed or seal integrity. This allows manufacturers to offer sustainable products while minimizing material waste and production costs.

Multi-Product Versatility

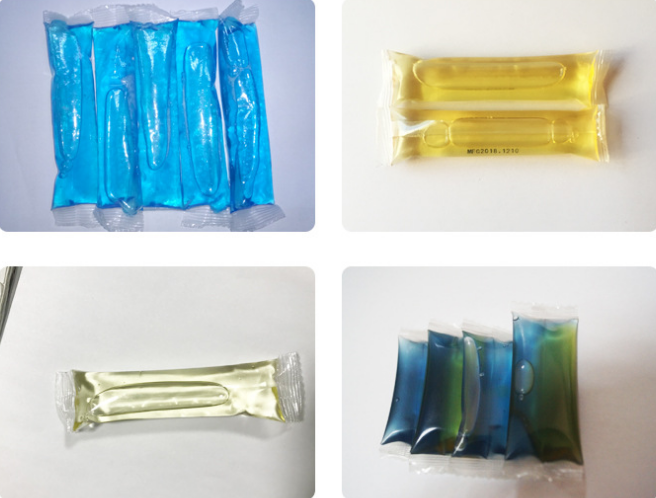

Another trend in water soluble packaging technology is the development of multi-functional machines capable of handling a wide range of products. Modern machines are being designed to accommodate powders, liquids, gels, and granules in single-dose formats. This versatility allows manufacturers to switch between product types without significant downtime or equipment modification, improving operational flexibility and maximizing return on investment.

Multi-product capability is especially beneficial for pharmaceutical and healthcare applications, where precise dosing and hygienic packaging are critical. Single machines that can handle multiple product forms reduce floor space requirements and streamline production lines, making them an attractive option for manufacturers with diverse product portfolios.

High-Speed and Multi-Lane Production

High-speed, multi-lane machines are becoming increasingly common as manufacturers seek to scale production while maintaining precision. Multi-lane configurations allow several packages to be produced simultaneously, significantly increasing output without requiring additional floor space. Combined with automated monitoring and precise dosing systems, these machines enable large-scale production of single-dose products while ensuring consistent quality and minimal waste.

Enhanced User Interface and Machine Intelligence

User interface improvements are another notable trend. Modern water soluble packaging machines are being equipped with intuitive touchscreens, real-time monitoring dashboards, and AI-assisted controls. Operators can adjust parameters quickly, monitor performance metrics, and receive alerts for potential errors. AI integration allows machines to learn from past production cycles, optimize processes, and predict maintenance needs, further improving efficiency and reducing operational risks.

Conclusion

The future of water soluble packaging machines is defined by automation, smart technologies, energy efficiency, multi-product versatility, and high-speed production. Advancements in machine intelligence, predictive maintenance, and data analytics are enabling manufacturers to produce single-dose packaging efficiently while maintaining product quality and sustainability. As environmental concerns and consumer expectations evolve, water soluble packaging machines will continue to adapt, offering flexible, reliable, and eco-friendly solutions across industries such as detergents, pharmaceuticals, and healthcare. These technological trends ensure that manufacturers can meet growing demand while minimizing operational costs and environmental impact.