In chemical manufacturing, maintaining precise process conditions is crucial for product quality, safety, and operational efficiency. Among the various parameters monitored in production processes, pH plays a significant role. Accurate measurement of acidity or alkalinity ensures optimal chemical reactions, reduces waste, and prevents damage to equipment. One of the most effective tools for achieving precise pH control is the pH sensor.

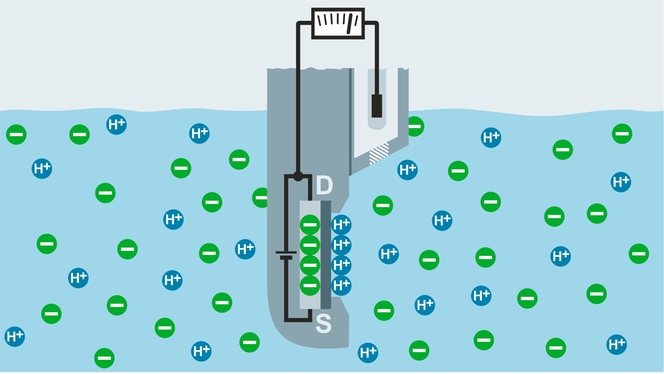

A pH sensor provides real-time monitoring of hydrogen ion concentration in chemical solutions. By integrating these sensors into manufacturing processes, operators can detect pH fluctuations immediately and implement corrective measures. This ensures that reactions proceed under ideal conditions, improving yield, reducing variability, and maintaining consistent product quality.

Optimizing Chemical Reactions

Chemical reactions are highly sensitive to pH levels. Even minor deviations can affect reaction rates, yield, and the formation of byproducts. Continuous monitoring with a pH sensor allows operators to maintain the optimal pH range, ensuring that reactions proceed efficiently. This is particularly important in processes involving acid-base reactions, polymerization, and chemical synthesis, where precise control determines the success of the operation.

By maintaining stable pH conditions, manufacturers can achieve higher reaction efficiency, reduce the need for reprocessing, and minimize the production of unwanted side products. This not only saves time and resources but also improves overall process reliability.

Enhancing Product Quality

Consistent pH monitoring ensures that chemical products meet stringent quality standards. Many manufacturing processes require specific pH conditions to achieve desired characteristics, such as solubility, stability, and appearance. Variations in pH can compromise product quality, leading to batch rejection or customer dissatisfaction.

Using a pH sensor enables real-time adjustments, maintaining uniformity across batches. Automated systems can utilize sensor data to control the addition of acids, bases, or buffers, ensuring that every batch meets precise specifications. This level of control supports regulatory compliance and enhances brand reputation.

Reducing Waste and Operational Costs

Monitoring pH accurately helps reduce raw material waste and operational costs. When pH levels deviate from the optimal range, additional chemicals or corrective actions may be required, increasing production costs. Continuous feedback from a pH sensor allows for immediate adjustments, minimizing chemical overuse and preventing unnecessary disposal of off-spec product.

Furthermore, preventing pH-related process failures reduces downtime and maintenance costs. Corrosion or scaling caused by improper pH levels can damage equipment and pipelines, leading to expensive repairs. By maintaining proper pH conditions, sensors help extend equipment life and improve operational efficiency.

Integration with Automated Systems

Digital pH sensors offer advanced features that enhance chemical manufacturing efficiency. They provide high-precision readings, automatic temperature compensation, and compatibility with automated control systems. This enables closed-loop control, where the sensor continuously informs dosing pumps or control systems to maintain target pH levels without manual intervention.

Integration into automation systems also facilitates data logging and process analysis. Manufacturers can track pH trends, optimize chemical usage, and improve process understanding, supporting continuous improvement initiatives.

Maintenance and Calibration

To ensure reliable performance, pH sensors require regular maintenance and calibration. Cleaning the electrode prevents residue buildup that can affect response time and accuracy. Routine calibration with standard buffer solutions aligns sensor output with true pH values, maintaining measurement precision over time.

Proper storage and careful handling further extend sensor lifespan. Following manufacturer guidelines for maintenance ensures consistent performance and reduces the risk of process disruptions.

Supporting Safety and Regulatory Compliance

Maintaining accurate pH control is also essential for safety. Many chemical reactions are exothermic or produce hazardous byproducts if pH deviates from specified ranges. Continuous monitoring with a pH sensor allows for early detection of deviations, preventing dangerous conditions and ensuring safe operation.

Accurate pH data also supports compliance with environmental and industry regulations. In processes that involve wastewater discharge or chemical effluents, monitoring and controlling pH is necessary to meet regulatory limits and avoid fines or environmental damage.

Conclusion

pH sensors play a critical role in improving efficiency, safety, and product quality in chemical manufacturing. By providing real-time, precise monitoring of solution acidity and alkalinity, these sensors allow manufacturers to maintain optimal reaction conditions, reduce waste, and prevent equipment damage. Integration with automated systems, combined with proper maintenance and calibration, ensures that pH sensors deliver consistent, reliable performance, making them indispensable tools in modern chemical production.