Operating a Swiss-type lathe requires both skill and attention to detail, especially when precision and efficiency are top priorities. These machines are designed to deliver exceptional accuracy and consistency, but even advanced equipment can underperform if not used correctly. Understanding common mistakes helps operators maintain high-quality output, reduce downtime, and extend machine life. For manufacturers focused on consistent production standards, avoiding these errors is essential.

When working with a swiss type automatic lathe machine, it becomes even more important to adopt proper procedures, because its unique sliding headstock and guide bushing design demand careful setup and monitoring. Many issues arise not from the machine itself but from incorrect handling or oversight during programming, tooling, or maintenance. Recognizing these pitfalls early can significantly improve performance and minimize waste.

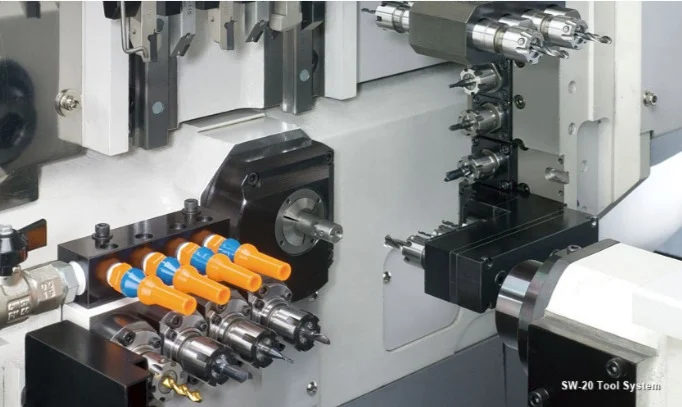

Incorrect Tool Selection and Setup

Tool selection is one of the most critical aspects of working with Swiss-type lathes. Using the wrong tool material, geometry, or size can lead to premature wear, poor surface finishes, and machining inaccuracies. Additionally, improper tool setup—such as an incorrect length or misaligned tool—can cause chatter, uneven cuts, and reduced part accuracy. Regular tool inspection and accurate calibration ensure smoother operations and longer tool life.

Overlooking Guide Bushing Adjustments

The guide bushing is fundamental to the precision of any Swiss-type lathe. A common mistake is failing to adjust or maintain it properly. When the bushing clearance is too large, workpiece deflection increases, resulting in dimensional errors. Conversely, overly tight settings cause excessive friction and wear. Operators should frequently check bushing conditions and ensure the correct clearance based on the material and diameter of the bar stock.

Inaccurate Programming and Feed Rate Settings

Programming errors often arise from incorrect data input, insufficient testing, or misunderstanding how certain functions interact within the control system. In particular, improper feed rates and speeds can lead to tool breakage or overheating. Swiss machines typically handle small, precise parts, so even minor programming mistakes can impact the entire batch. Running test cycles and validating tool paths before full production helps avoid costly issues.

Poor Coolant Management

Coolant plays a major role in temperature control, lubrication, and chip removal. A common oversight is not monitoring coolant levels or failing to maintain the correct mixture. Low coolant volume or improper concentration leads to overheating, faster tool wear, and poor chip evacuation. Operators should regularly check filters, coolant concentration, and flow direction to ensure optimal machine performance.

Neglecting Routine Machine Maintenance

Swiss-type lathes demand regular maintenance to operate at their best. Skipping scheduled checks or delaying cleaning can cause issues such as spindle wear, buildup of chips, and lubrication failures. Over time, these problems compromise machine accuracy and lead to unexpected downtime. A disciplined maintenance plan, including lubrication checks, alignment inspections, and cleaning routines, helps preserve long-term reliability.

Incorrect Bar Stock Preparation

Improperly prepared bar stock is another frequent issue. Bent, dirty, or poorly cut bars can cause feeding problems and vibrations during machining. Even slight imperfections affect how the stock interacts with the guide bushing, impacting part quality. Ensuring bar stock is straight, clean, and appropriately chamfered before loading can prevent many operational difficulties.

Inadequate Chip Control

Swiss-type lathes generate fine, continuous chips due to the nature of the cutting process. Without proper chip control, these chips can wrap around tools, block coolant flow, or damage part surfaces. A mistake many operators make is ignoring chip buildup or relying solely on coolant to clear debris. Using appropriate chip-breaking tools and monitoring chip evacuation helps maintain stable machining conditions.

Skipping Test Runs and Quality Checks

Rushing into full production without conducting preliminary tests is a common error that leads to scrap and rework. Since Swiss-type lathes produce high-precision components, verifying dimensions, surface finishes, and tolerances early in the run prevents larger issues. Regular in-process inspections ensure consistent quality and reduce the risk of producing an entire batch of defective parts.

Conclusion

Mistakes in using Swiss-type automatic lathes often stem from oversight, insufficient preparation, or neglect of proper machine care. By paying attention to tool selection, guide bushing adjustments, programming accuracy, and routine maintenance, operators can prevent many common issues. Effective coolant management, chip control, and quality checks also contribute to smoother operations and better output. Avoiding these errors not only enhances productivity but also extends machine life, ensuring reliable and precise performance across every production run.