In modern manufacturing, precision and efficiency are crucial for producing high-quality components. Industries such as medical devices, electronics, aerospace, and automotive increasingly rely on advanced machinery to maintain tight tolerances and consistent output. Swiss lathes have emerged as a cornerstone of precision manufacturing due to their ability to produce intricate parts with exceptional accuracy. Understanding how these machines enhance manufacturing processes can help workshops make informed investment decisions.

Enhanced Accuracy and Repeatability

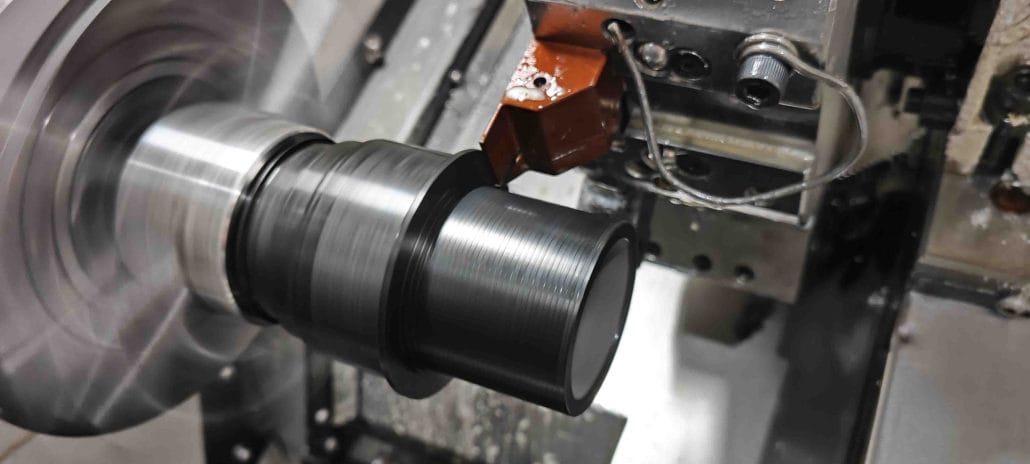

One of the primary benefits of investing in a swiss lathe for sale is the remarkable precision it offers. Unlike conventional lathes, Swiss-type machines feature guide bushing support that minimizes deflection during cutting. This design ensures that small-diameter components maintain dimensional accuracy, even during long production runs. Additionally, CNC control allows for highly repeatable operations, reducing variability between parts and ensuring consistency across batches. This level of precision is particularly important in industries where minor deviations can lead to product failure or regulatory non-compliance.

Versatility in Complex Machining

Swiss lathes are renowned for their versatility in handling complex geometries. Multi-axis CNC capabilities enable simultaneous operations, such as turning, drilling, and threading, which would otherwise require multiple machines. This consolidation of processes not only improves precision but also streamlines production, reduces handling errors, and shortens lead times. By combining advanced tooling options and automated features, Swiss lathes allow manufacturers to produce intricate designs with high repeatability and minimal waste.

Reduced Material Waste and Operational Efficiency

Precision machining directly contributes to operational efficiency. The support structure of a Swiss lathe reduces tool deflection and vibration, which minimizes the risk of scrap parts. Accurate, repeatable operations also decrease the need for secondary finishing or rework, saving both time and materials. Over time, this efficiency translates into lower production costs and faster turnaround times, making Swiss lathes a cost-effective solution for high-volume manufacturing that demands exacting standards.

Integration with Automation and Advanced Controls

Modern Swiss lathes often incorporate advanced control systems and automation capabilities. CNC programming, coupled with automated bar feeders and robotic part handling, enables continuous operation with minimal operator intervention. This integration not only maintains consistent quality but also increases throughput. Manufacturers benefit from a streamlined workflow where machines can operate around the clock, producing precise components reliably without frequent manual adjustments.

Quality Assurance and Compliance

Maintaining quality standards is critical in precision manufacturing. Swiss lathes enhance quality assurance by producing parts that meet strict dimensional tolerances and surface finish requirements. This consistency is essential for industries such as medical device manufacturing, where adherence to regulatory standards is non-negotiable. By reducing variability and ensuring uniformity, Swiss lathes support compliance while minimizing the risk of costly errors or recalls.

Long-Term Reliability and Investment Value

Investing in a high-quality Swiss lathe is not only about immediate precision but also long-term reliability. Machines built with robust frames, stable spindles, and advanced cooling systems maintain accuracy over extended periods of operation. This durability ensures that manufacturers can rely on their equipment for high-volume production while minimizing downtime and maintenance costs. In the long run, the initial investment pays off through consistent quality, reduced waste, and improved overall productivity.

Conclusion

A Swiss lathe for sale offers manufacturers the ability to achieve exceptional precision, versatility, and operational efficiency. From producing complex components to reducing material waste and ensuring regulatory compliance, these machines are instrumental in modern precision manufacturing. By integrating advanced controls, automation, and durable construction, Swiss lathes provide a reliable solution that enhances both productivity and product quality, making them a valuable asset for any workshop focused on high-precision manufacturing.